DX

I

ndustrial

V

FD

P

anel

508 A Panel Shop

508 A Panel Shop

230 V & 460 V

230 V & 460 V

Easy Setup Wizards

Easy Setup Wizards

Nema 3R Outdoor Enclosure

Nema 3R Outdoor Enclosure

5 – 800 HP

5 – 800 HP

508A Panel Shop

Simple Constant Pressure Setup

Made In The USA

Industry Best Lead Times

Economical

Three-Phase Motor Control

Phase Technologies DX offers advanced motor control for three-phase input and output applications, delivering precise speed and torque for industrial and commercial environments.

A

merican

M

ade

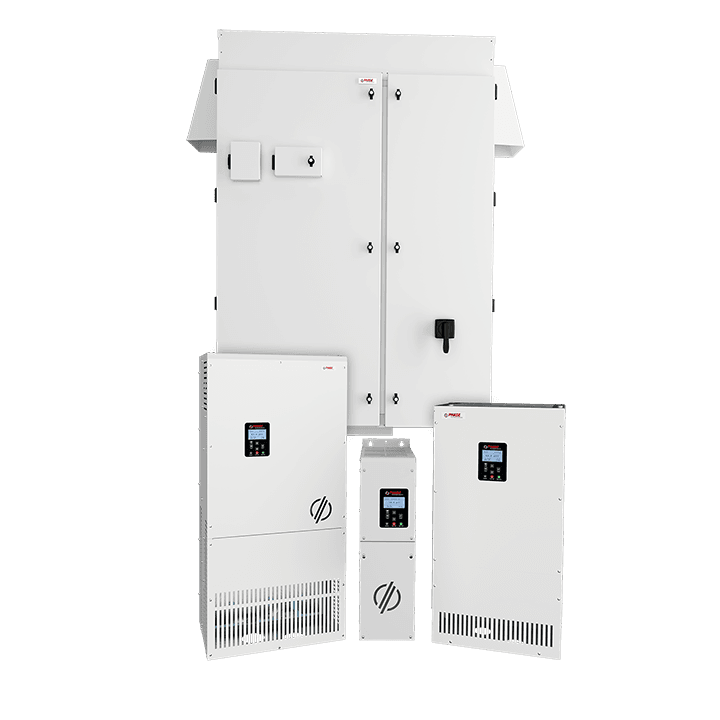

An American-manufactured panel with capabilities for applications up to 800 HP, Phase Technologies’ DX (Industrial) VFD panels are the solution to your motor control problems. Purchase as a standalone drive or customize your unit in an enclosed panel configuration using our 508A panel shop. Additionally, take advantage of add-on components to increase the efficiency and performance of your unit.

R

ugged

D

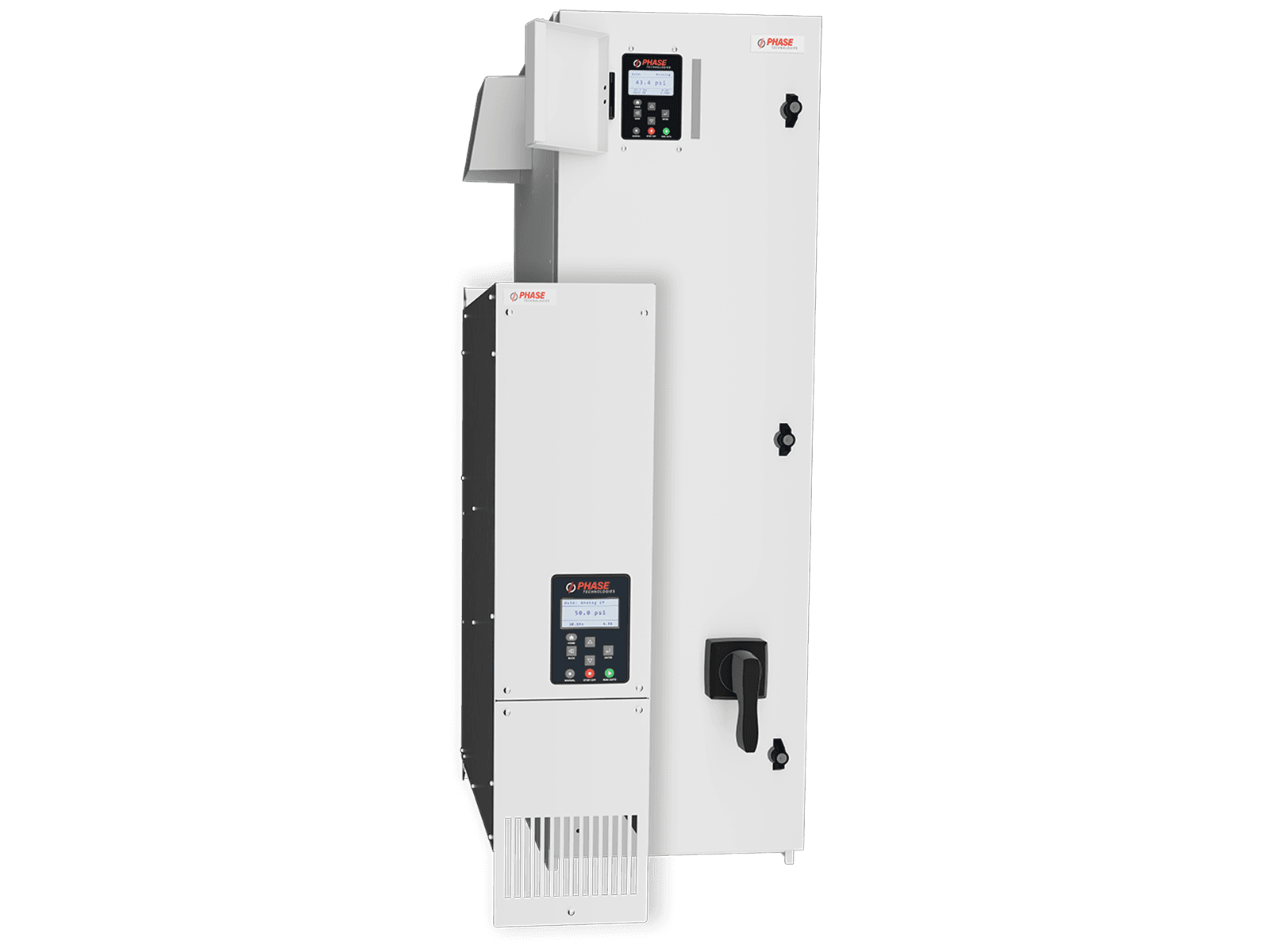

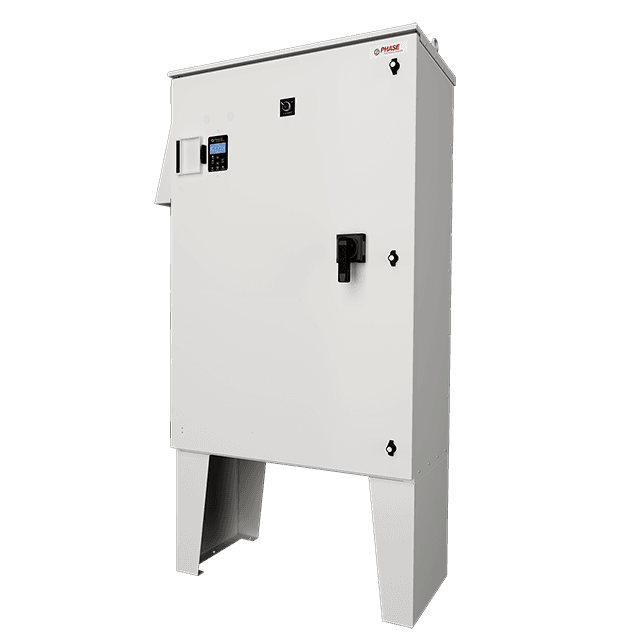

esign

Protect your investment with our all-steel, NEMA 3R enclosures, guaranteed to keep out the elements while allowing your panel to operate at peak performance. All our enclosures are made in-house at our metal fabrication shop, ensuring the highest quality products, proudly made in America.

Perfect Pressure

Easy Setup Wizard

Set Up Constant Pressure in Minutes

Identical Keypad & Setup Across All Models

Large Backlit Display with Intuitive Menus

Simple Messages in Clear English

The Perfect Pressure™ Easy Setup Wizard is a user-friendly tool integrated into our VFDs to simplify the configuration of constant water pressure systems. Upon initial startup, the wizard guides users through a series of prompts to establish the desired pressure settings. This streamlined process allows for quick and efficient setup, often requiring only a few minutes to complete.

Perfect Pressure™ Setup Process

Configure a pump system to deliver constant pressure with just a few button presses. After the setup wizard, validate the system and walk away knowing it will supply constant pressure no matter the demands placed on it.

Most Variable frequency drives are hard to configure. Needing to hunt through a complex manual trying to cross-reference parameters, while trying to configure them on barely readable screen was normal. Phase VFD’s still have all those parameters under the hood if you want to fine-tune a pump system, but our intuitive wizard will have you running in just a few seconds.

Try this interactive Perfect Pressure™ Wizard to see how easy it is!

Run Constant Pressure? STEP 1

On start, use the arrows to toggle to "Run Constant Pressure Wizard?" - Press the ENTER key to proceed.

4-20mA psi RANGE STEP 2

Set the psi range of the 4-20mA sensor. Default is 150psi. Press ENTER to proceed.

psi SETPOINT STEP 3

Determines the pressure you want to maintain. The factory default is 50 psi. Use the arrow keys to change if desired. Press ENTER to proceed.

SUBMERSIBLE PUMP STEP 4

This parameter sets the ramp profile for a submersible pump. "YES" = ramps to 30HZ in the first second to prevent excessive wear on the thrust bearing. "NO" = The frequency will increase in a linear fashion from zero to max frequency. Use the arrow keys to toggle between the two settings. Press ENTER to proceed.

Disable Manual Mode STEP 5

The "Yes" value allows you to disable the MANUAL button run mode. "No" allows you to run the VFD manually on/off at max frequency.

OVERCURRENT LIMIT STEP 6

Setting for motor overload protection (service factor amp rating for the motor) using the arrows to toggle. Press ENTER to proceed.

RUN/AUTO STEP 7

Press the RUN/AUTO button to start the pump.

Click Enter!

9.1

Yes (Enter)

No (Back)

Perfect For All Applications

Available as a stand alone drive and enclosed panel configuration

Power conditioning for smooth power input

Easy Set Up Wizards preprogrammed in your system for quick and easy startup

Great for all industrial applications

Irrigation

Livestock

Sewer Bypass

Lift Stations

Craft Your Configured Panel

Design the right DX unit for your operation, and we will provide the perfect enclosure. Take advantage of our wide range of add-on components to enhance the efficiency and performance of your configured panel. Phase Technologies will build your unit to spec, at our manufacturing facility, and ship it directly to your home or business for easy installation.

The DXL line is powered by our DXL variable frequency drive, combined with our configured panel options, to bring you a custom unit for your operation.

MCCB – Service rated

HOA Switch

Speed Pot

Line Reactor

Run & Fault Light

Output Filter

Bypass

Surge Protection

- Protec

- Strikesorb

Leg Kit

10-DAY

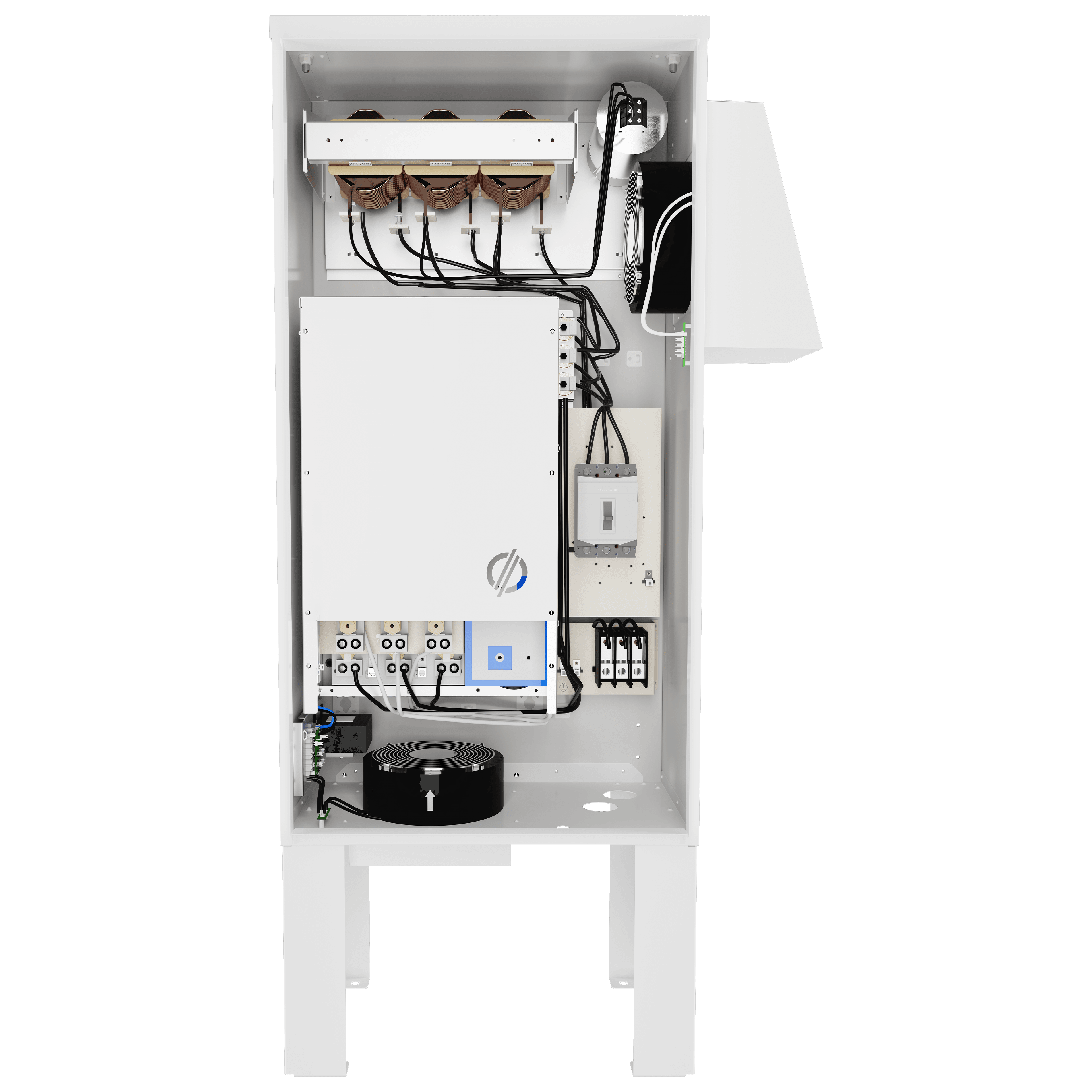

Inside The Panel

Engineered for maximum performance with minimal components, Phase Technologies configured panels are the definition of simplicity and efficiency. Gone are the days of large enclosures with small drives, heaps of wires, and bulky components. Enjoy the perfectly sized enclosure with all the necessary add-ons, intuitively crafted into a 3R enclosure.

Drive: The DX is powered by a Phase Technologies DXL VFD

Enclosure: Configured panels come standard with NEMA 3R all steel enclosures made in house.

Circuit Breaker: Protect your drive with a Circuit Breaker, which is available in our 508A panel shop.

Line Reactor: All panels include an integrated DC Choke standard above 30 HP

Output Filter: Built with components to limit peak voltage, these filters are recommended with lead lengths up to and above 1,000 feet.

Product Overview

Input: 230 V, 3Φ

| Model | Horsepower | Input Voltage | Output Voltage | Related Input Current | Related Output Current | Configure |

|---|---|---|---|---|---|---|

| DX005R | 5 | 230 | 230 | 18 A | 18 A | |

| DX007R | 7.5 | 230 | 230 | 25 A | 25 A | |

| DX010 | 10 | 230 | 230 | 31 A | 31 A | |

| DX015R | 15 | 230 | 230 | 46 A | 46 A | |

| DX020R | 20 | 230 | 230 | 61 A | 61 A | |

| DX025R | 25 | 230 | 230 | 75 A | 75 A | |

| DX030R | 30 | 230 | 230 | 91 A | 91 A |

Input: 460 V, 3Φ

| Model | Horsepower | Input Voltage | Output Voltage | Related Input Current | Related Output Current | Configure |

|---|---|---|---|---|---|---|

| DX405R | 5 | 460 | 460 | 9 A | 9 A | |

| DX407R | 7.5 | 460 | 460 | 13 A | 13 A | |

| DX410R | 10 | 460 | 460 | 18 A | 18 A | |

| DX415R | 15 | 460 | 460 | 25 A | 25 A | |

| DX420R | 20 | 460 | 460 | 31 A | 31 A | |

| DX425R | 25 | 460 | 460 | 38 A | 38 A | |

| DX430R | 30 | 460 | 460 | 46 A | 46 A | |

| DX440R | 40 | 460 | 460 | 61 A | 61 A | |

| DX450R | 50 | 460 | 460 | 77 A | 77 A | |

| DX460R | 60 | 460 | 460 | 86 A | 91 A | |

| DX475R | 75 | 460 | 460 | 101 A | 107 A | |

| DX4100R | 100 | 460 | 460 | 134 A | 142 A | |

| DX4125R | 125 | 460 | 460 | 163 A | 172 A | |

| DX4150R | 150 | 460 | 460 | 188 A | 198 A | |

| DX4200R | 200 | 460 | 460 | 237 A | 250 A | |

| DX4250R | 250 | 460 | 460 | 288 A | 304 A | |

| DX4300R | 300 | 460 | 460 | 346 A | 365 A | |

| DX4350R | 350 | 460 | 460 | 394 A | 415 A | |

| DX4400R | 400 | 460 | 460 | 454 A | 478 A | |

| DX4500R | 500 | 460 | 460 | 560 A | 590 A |

Input Power

Input Phase | Single-Phase or Three-Phase |

|---|---|

Input Voltage | 230 V | 460 V |

Input Voltage Range | 190 V — 264 V | 440 V — 520 V |

Input Frequency | 50/60 Hz |

Output Power

Output Phase | Three-Phase |

|---|---|

Nominal Output Voltage | 230 V | 460 V |

Output Voltage Range | 100 V – 270 V | 200 V — 530 V |

Output Frequency | 5 Hz – 120 Hz |

Horsepower | 5 HP - 700 HP |

Output Power | 1.5 - 409 kW |

Switching Frequency | 2 kHz – 5 kHz |

Output | V/f control Torque Control (Optional) |