Single Phase to Three Phase Conversion

What is phase conversion?

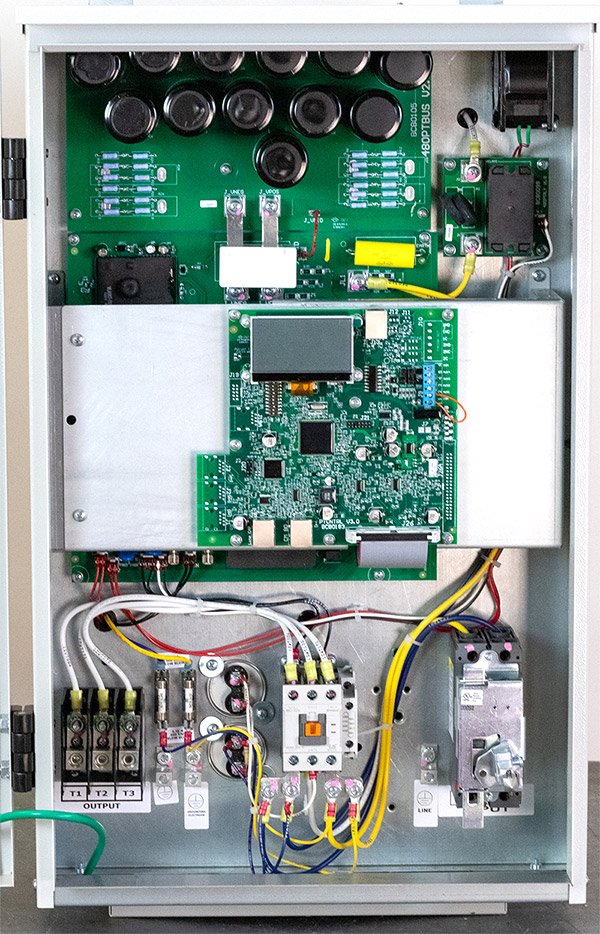

A phase converter is a device that produces three-phase electrical power from a single-phase source, allowing the operation of three-phase equipment at a site that only has single-phase electrical service.

The first phase converters were invented nearly one hundred years ago. Static phase converters have changed little since that time. Since then, new types of phase converters have been developed, driven by the available technology and the needs of ever more modern equipment.

Why would I need phase conversion?

A large number of applications and equipment once considered "industrial" require three-phase power. The general use of three-phase equipment is increasing on farms and ranches, in home wood and metal shops, or in other locations where utility-provided 3-phase isn't readily available. Even when 3-phase is available nearby, the costs of bringing in new service, adding additional transformers and wire can drive costs upward of $50,000.

How do I choose the right phase converter?

Phase Technologies manufactures modern and highly efficient digital phase converters and variable frequency drives (VFD's) for virtually any application. Use the following guide to determine what the best solution is for your use-case. If you need help or have questions please call our expert sales staff for assistance.

When to use a Digital Phase Converter

-

To Simultaneously Power Electronics and Motors

Only the Phase Perfect® digital phase converter, with its patented solid-state technology, provides a safe, clean, three-phase output which is capable of starting and stopping motors across the line while running electronics such as transformers, contactors, circuit boards, lights, and heaters.

-

To Power Multiple Loads

While a single VFD enables multiple loads to run at one time, they must all be started and stopped together, or control issues may result. However, unlike a VFD, the Phase Perfect® digital phase converter provides the flexibility needed to start, stop and run equipment at different times.

-

Equipment Designed With Internal VFDs

Equipment designed with internal VFDs shouldn’t be controlled by an external VFD. This type of equipment is not meant to be started and stopped by the source power. While it may seem counterintuitive, a VFD powering another VFD will damage the system.

For loads such as CNC, HVAC, and elevators, a Phase Perfect® Digital Phase Converter is recommended.

Read common questions and answers about phase convertersWhen to use a Variable Frequency Drive

-

For Motor Control

A VFD starts, stops and controls the speed of motors, as well as communicates with other systems such as sensors, floats, and programmable logic controllers (PLC).

-

As A Soft Start

A VFD ensures a “true soft start” which means that it won’t allow the motor to exceed its rated run current during start up.

-

For Constant Pressure Control

A VFD maintains constant system pressure by automatically varying pump speed in reaction to changes in system pressure.

-

If Electronics Are Not Present

A VFD can ONLY run motor loads. Never connect a VFD to a device that contains electronics such as, but not limited to, transformers, contactors, circuit boards, lights, and heaters.

-

For Pivot Applications

Phase Technologies manufactures a VFD system with an output to run a pumping system and a digital phase converter to run a pivot at the same time. (See the 1LH Series with AUXPOWER™ systems). This VFD system phase converts power, runs a constant pressure system, and provides sinusoidal power simultaneously to efficiently operate a pivot with electronics and GPS.

Three-phase power as good as the utility provides. In many cases you can get away without having perfect three-phase power and still get the job done. Those applications are becoming fewer and fewer, however. Power efficiency mandates, smart or internet connected devices, and modern safety features mean computers are being embedded in more and more devices where you may not have expected to find them in the past. Running these devices on a Phase Perfect® will ensure they run as well as they would with utility three-phase and protect these delicate embedded electronics.

Read more about thePhase Perfect®

Phase Technologies VFD's featuring modern phase conversion technology

A variable frequency drive (VFD), such as the Phase Technologies 2XD or 1LH series, is commonly used as a phase converter in pumping applications. VFD's are becoming the standard for pumping because they allow you to take advantage of variable speed, soft starting and stopping, constant pressure water systems, and advanced pump and well protection features.